Stakeholders in the EPD Life Cycle

This is a continuation of the previous post

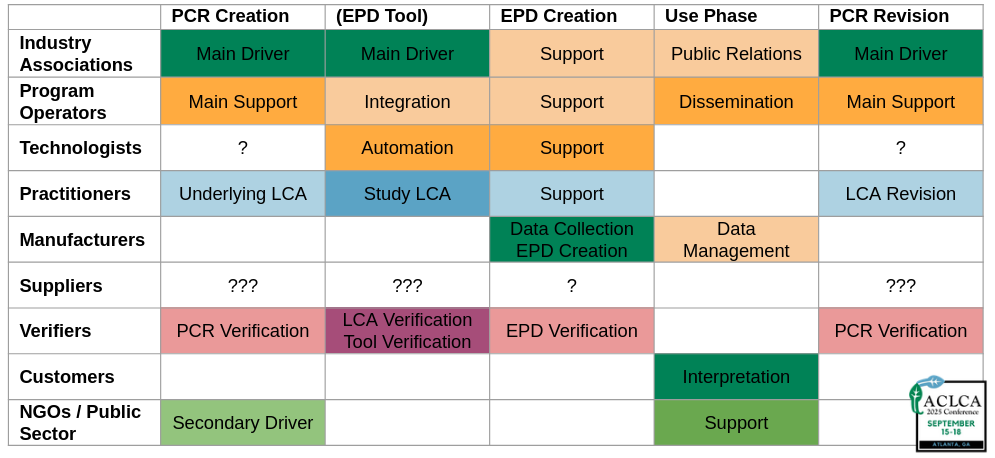

The process of preparing an Environmental Product Declaration (EPD) begins long before an individual firm starts collecting data on their fuel use and emissions. Every EPD is the product of a vast array of stakeholders participating in a variety of ways.

Every EPD program is the result of many people working over many years.

According to ISO 14025, every EPD is prepared in accordance with a Product Category Rule (PCR), which specifies the scope, LCA modeling requirements, and other constraints on how the EPD is to be prepared. The main purpose of this requirement is to improve consistency and comparability of LCA studies of the same type of product prepared by different parties (although there is some evidence that they do not accomplish this goal as well as we might hope).

Many hands, heavy work

This means that before EPDs can even be prepared, a PCR must drafted, reviewed, and approved — a lengthy process that depends on the voluntary participation of industry representatives and LCA specialists. The process is usually driven by an industry organization that represents manufacturers of the “product category” in question, and it is often facilitated by a Program Operator, which is a (generally for-profit) organization that will ultimately publish the EPDs and facilitate public access to them.

EPD Automation at the PCR level

The PCR provides the requirements that must be met for every EPD under it, so it is the first place for the creators of automated EPD tools to look. The most successful automated EPD generator tools in North America were created by people who were directly involved in the PCR process:

cement and concrete, run by Climate Earth, under an EPD program operated by the National Ready Mix Concrete Association;

Emerald Eco-Label for hot-mix asphalt, under an EPD program run by the National Asphalt Pavement Association

Even with this tight integration, both of these programs took years to develop. In order to reduce the complex and open-ended process of performing an LCA into a turn-crank operation, all aspects of that complexity must be represented. In order for the results to be meaningful and believable, the process must be subjected to verification, both during tool development and afterwards, when actual EPDs are issued.

What can LCA practitioners do to facilitate verification throughout the EPD life cycle?

The answer is that we can be crystal-clear about what exactly we are verifying.

The standard for PCR development (ISO 14027) is very vague. In the world of buildings and construction materials, an additional standard (ISO 21930) which is quite exhaustive and functions as a “core” PCR for any and all products in this category (ISO 21930 is the point of origin for the familiar “A1-A2-A3” module descriptions describing cradle-to-gate manufacturing).

ISO 21930 system boundary table showing the familiar “A1-A5, B1-B7, C1-C4 and D” module specification.

But other product categories aren’t so lucky, and even within the buildings-and-construction space, a lot is still left to the practitioner.

PCR committees can solve that by being very explicit about what they are requiring

LCAs are not actually that complicated

A nearly-complete specification of the FHWA Asphalt Framework model.

The image above shows nearly-complete rendition (in Excel) of the “FHWA Asphalt Framework” that underlies the Emerald Eco-Label tool. This product system model is available in the Federal LCA Commons for anyone to inspect. And the description above has almost everything there is to know about it. The technical committee for the hot mix asphalt PCR has leaned heavily on this description in crafting its rules and requirements, going so far as to mandate the use of specific background datasets and allowable bounds for different exchange values.

This table of exchanges provides a blueprint for verification of EPD results. In the next post, I’ll talk about how other PCR committees should follow the examples of hot mix asphalt, and cement and concrete, to stand on exchange specifications for writing verifiable PCRs.